| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Lever

Model Number : LV-TB-V-L

Certification : CE

Place of Origin : China

MOQ : 1 SET

Payment Terms : T/T,or L/C

Delivery Time : 90-120days

Packaging Details : Container or wooden case

Automotive sidelites glass : Automotive backlites glass

auto side glass : auto rear glass

automobile side door glass : automobile backscreen

auto glass : back windshield glass

1. Machine Application

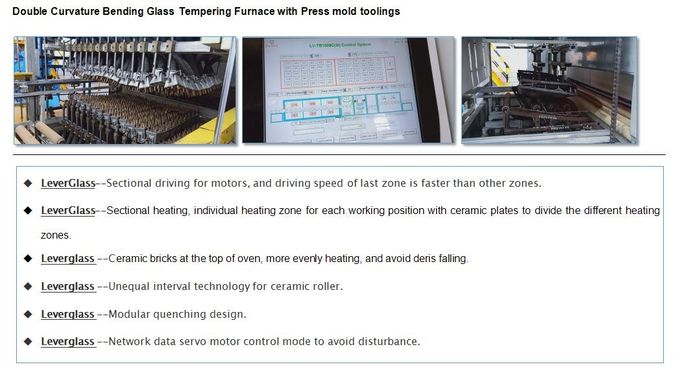

LV-TB-V-L Series Bi-direction Single & Double Curvature Bending Glass Tempering Machine is a special plant used to produce the bent tempered glass for automobile side lite and back lite, also for trucks, furniture, etc. Our customer produced the side doors for BMW, Audi, Toyota, Honda, Hyundai, Peugeot, etc.

2. Supply Scope:

2.1. Loading table

2.2. Single Bent tempering & cooling section

2.3. Heating section

2.4. Double bend Forming section with mould

2.5. Quenching section

2.6. Transmission section

2.7. Cooling section

2.8. Unloading table

2.9. Blower system

2.10. Electrical & control system

3. Popular size:

1600x800mm, 1600x1000mm, 1800x1000mm

2000x1000mm, 2000x1200mm, 2200x1200mm

4. Machine Main Features:

4.1. In the bending forming, for transmission of pressing mould, support mould and rollers, we use servo motors & servo controllers.

4.2. In quenching section, for transmission of mould carrier, we use servo motors & servo controllers.

4.3. Equipped with heating & insulating system in forming section, which could keep temperature of the forming section so that the glass is formed in high temperature.

4.4. Easy-making and cheap moulds

4.5. Easy & quick moulds changing-time

4.6. Smaller roller distance in heating oven which guarantee the high quality

4.7. Heating section has a helix matrix structure, which can control the temperature of each area independently. Reasonable design and unique structure of heating elements make a long serve life.

4.8. The heating oven body is full closed and the Insulating materials are of high quality material with top performance which can ensure very lower energy consumption.

4.9. Ceramic roller: World-famous brand

4.10. Ceramic roller driving adopts seamless round belts.

4.11. Fault diagnosis system for the heating elements.

Lever Industry Co have more than 19 years of experience in the Glass Processing Industry.

We are Unremitting, Just for Customer Satisfication!

|

|

Dual direction Glass Toughening Furnace , Single & Double Curvature Bending Glass Tempering machine Images |