| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Lever

Model Number : LV-TB-L

Certification : CE

Place of Origin : Luoyang city, China

MOQ : 1 set

Price : FOB Qingdao port, USD280000 per set

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 100 SETS PER YEAR

Delivery Time : 120 Days

Packaging Details : seaworthy

Product Name : Automotivel Side Window Glass tempering furnace

Application : Automotive glass, sidelites, side window

Production capacity : 120Load/per hour for 3.2mm

capacity : customerized, & Continuous bending type available

ceramice rollers : World best Vesuvius brand

Max. glass size : 1200*900mm

Glass Thickness : 3.2-6mm

PLC : Siemens brand

Voltage : 380V 50HZ,Customerized,380V/415V/ 220V,380V 50HZ/60HZ

Condition : New

After-sales service provided : Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training

Weight : about 24000KG

Power(w) : 500KVA,Depend

Color : Customers' Request,gray,Customized

Usage : tempered glass,Glass tempering,Make Toughened Glass,doors and windows,side doors of automotives

Product name : High end toughened glass tempering furnace manufacturers,Factory direct Low price car glass toughened Furnace

Warranty : One Year,1 year,12 Months

Name : glass tempered machine,Glass tempered and toughened glass furnace,Horizontal Glass Tempering Machine

Heating method : radiation heating

Min glass size : 150*300mm

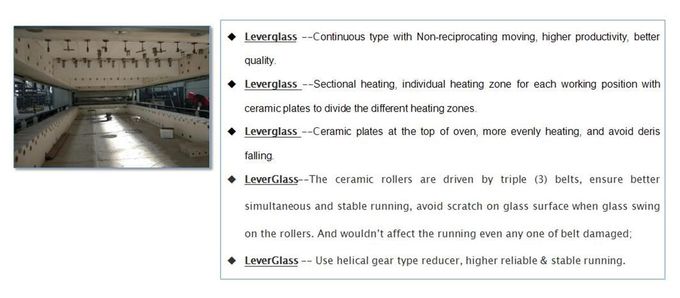

Bending Tempering machine for Automotive Side window glass with high production and high precision, LV-TB-L Series

1. Machine Application

Continuous Bending Glass Tempering Machine is a special plant used to produce the bent tempered glass, which mainly used in the fields of side windows (sidelites) of automotives, trucks, shower room, furniture, etc. The side door of the automotive should be single curvature. Our customer produced the side doors for BMW, Audi, Toyota, Honda, Hyundai, Peugeot, etc.

| Model | Max. Loading Area | Min.Glass Size | Thickness | Min.Radius |

| (mm) | (mm) | (mm) | (mm) | |

| LV-TB1206L | 1200 x ⌒600 | 150 x 280 | 3.2~6 | ≧1000 |

| LV-TB1608L | 1200 x ⌒800 | 150 x 280 | 3.2~6 | ≧1000 |

| LV-TB2010L | 2010 x ⌒1000 | 150 x 280 | 4~6 | ≧1000 |

2. Main Technical Features:

►. The bending forming is with servo motors & servo controllers which from Yaskawa, Japan.

►. Higher precision and speed arc-changing.

►. Most advanced bending forming technology in China. Easy & accurate arc-adjustment. The glass type change could be finished within few minutes.

►. Helix matrix structure for heating oven, which can control the temperature of each area independently.

►. Full closed heating oven and high quality Insulating materials with top performance which can ensure a minimum power consumption and uniform oven temperature.

►. Fault diagnosis system for the heating elements.

►. PID temperature control,

►. Preventive function for the wrong operation

►. Synchronous and asynchronous running of each section

►. Power monitoring function

►. Suitable for processing clear float glass, patterned glass, reflective glass, low-e glass, etc.

►. Standard for processed products: GB15763.5, GB9656, EN12150-1:2000, ECER-43, ANSIZ97.1, etc.

Lever Industry Co have more than 19 years of experience in the Glass Processing Industry.

We are Unremitting, Just for Customer Satisfication!

|

|

Glass Tempering Furnace Glass Toughening Furnace With High Precision Images |